products

Innovative suspension solutions

Mercedes Benz, Volvo, MAN, Nissan, Renault, Scania, Iveco, and Isuzu... all of these companies and many more trust MBHA year after year for for the quality of our products, but most importantly for the excellence of our service.

For MBHA, innovation is the perfect fusion of human ability and technology prowess. The union of human expertise, judgement, and vision with the scope, precision, scale, and reliability of state-of-the-art technology, enabled by cutting-edge R&D processes. For commercial vehicle manufacturers seeking well-designed, reliable, safe, and high-quality suspension components without having to sacrifice a close, flexible, and helpful relationship, MBHA is the brand that empowers them to have the highest quality service while ensuring continuity built on awareness, professionalism, and comprehensive adaptability to their needs.

Quality

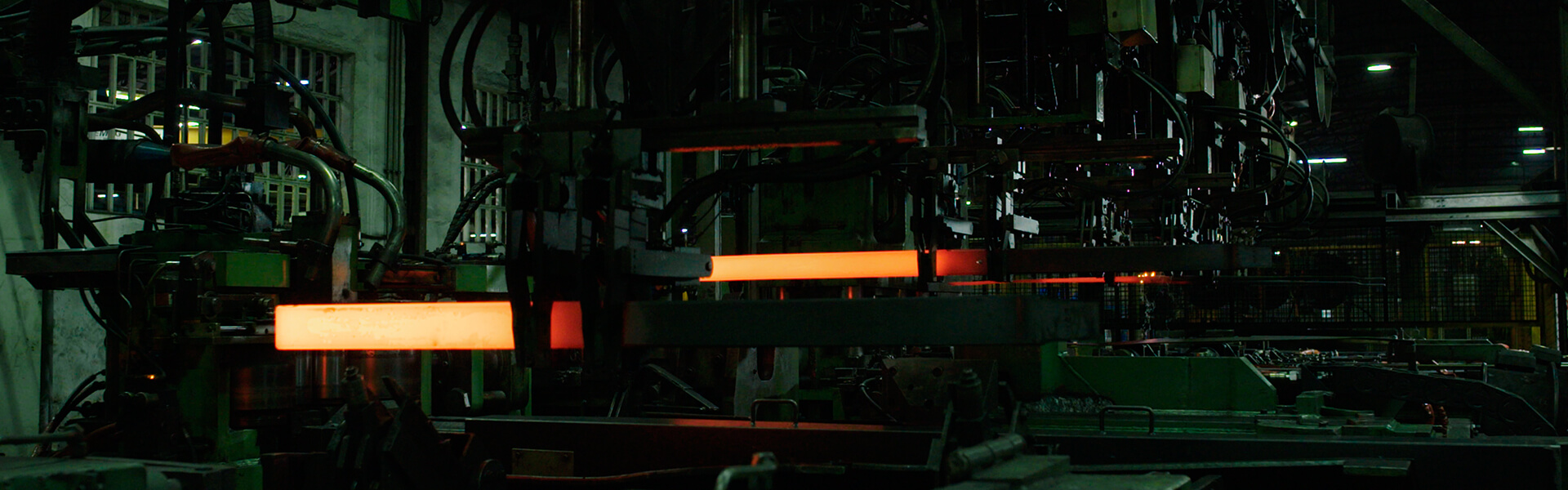

Springs manufactured with cutting-edge technology to ensure the highest quality.

Safety

A product that guarantees maximum safety under all conditions.

Reliability

Due to our constant improvement processes, we offer the best level of reliability on the market.

Innovation

Our unwavering dedication to R&D ensures that we are constantly one step ahead.

Steel Leaf Springs

We design and produce all types of leaf springs for light, medium and heavy trucks.

Monoleaf

A technologically advanced single-blade leaf spring. The achieved stresses enable maximum utilization of the steel, resulting in weight savings. The design of this leaf spring requires the use of extremely high-quality steels and a high level of process control, as they cannot be manufactured in just about any facility.

Parabolic Leaf Springs

The rolling profile of these leaf springs follows a parabolic function. With this distribution, a constant stress level is achieved over the entire leaf spring branch under all stress levels. This results in better material utilisation compared to semi-elliptic or "traditional" leaf springs. They can be manufactured with one or two stiffnesses, depending on the design.

Pneumatic Leaf Springs

This type of spring is used in the air suspension from which it takes its name. While the steel springs above are able to take over part of the axle guidance, an air cylinder can only absorb vertical loads. By using air springs, it is possible to utilise the advantages of an air suspension without losing the aforementioned guidance. These springs therefore have the dual function of retaining the guidance and supporting the air cushion.

Pendelfeder

This type of leaf spring, unlike the others, controls two axles of the vehicle. Unlike other leaf springs, the leaf spring is attached to the truck at the centre and the axles are joined at both ends of the leaf spring. They are used on construction or heavy-duty vehicles. They can be manufactured with one or two stiffnesses, depending on the design.

Multileaf

Leaf springs that usually consist of a large number of blades with a constant cross-section. Technically simpler to manufacture. Their robustness and ease of repair mean that they are still used in many applications. As in previous cases, it is possible to design them with one or more stiffnesses.

Lighter

A weight reduction of 30% to 90% compared to its steel counterpart.

Stronger

Excellent mechanical properties combined with a high level of fatigue resistance.

Suppler

Superior flexibility for even greater longevity at full performance.

Sturdier

Superior strength and corrosion resistance for increased durability.

Monolam Front Leaf Spring

Leaf spring consisting of a single leaf made of composite material. The parabolic profile optimises the use of the material in relation to the forces. The eyelets are also made of composite material. This type of leaf spring is designed to control the front axle of the vehicle.

Overall weight reduction

Hybrid Front Leaf Spring

Front leaf spring consisting of a main steel leaf and a second leaf made of GFRP. The parabolic profile optimises the use of the material in relation to the stresses. This type of leaf spring is designed to control the front axle of the vehicle.

Overall weight reduction

Full Composite Tandem Leaf Spring

Tandem type rear leaf spring made entirely of GFRP. In this case, the leaf spring also consists of a main spring and a leaf spring. In this way, two stiffness ranges can be offered for greater comfort depending on the truck load.

Overall weight reduction

Hybrid Trailer

Trailer leaf spring consisting of a main steel leaf and a second leaf made of GFRP. The parabolic profile optimises the use of the material in relation to the stresses, making it possible to reduce from an 11-leaf leaf spring to a 2-leaf leaf spring.

Overall weight reduction

Hybrid Tandem Leaf Spring

Tandem type rear leaf spring consisting of a steel main leaf and a GFRP second leaf.

Overall weight reduction

Monolam for Trailers

Trailer leaf spring consisting of a single GFRP leaf. The parabolic profile optimises the use of the material in relation to the stresses and can be reduced from an 11-leaf leaf spring to a single leaf spring.

Overall weight reduction

To find out more about what Ziur Composite Solutions offers and the MBHA Group's commitment to a light and sustainable future, visit its website and discover how we help different industries through the development of projects based on composite materials.

360º SERVICE

The best product and service possible as a result of our commitment to excellence.

R+D+I Centres

We develop projects with advanced technological content, from product and process design to the homologation of the products with our own R&D team.

We promote research, development and innovation to obtain new technological solutions, which continuously improve our know-how. More than 50 years in the sector, as well as the know-how acquired by our engineers, allows us to propose the most optimal solutions, being pioneers in the presentation of solutions of high technological value, enabling us to manufacture all types of prototypes for our customers.

Product Design

Through its R&D Department, MBHA Projects offers its customers the opportunities to partner on the design and subsequent development of all types of leaf springs and other components.

Both the use of CAD tools and the following Finite Element analysis of the leaf spring during installation enable us to optimize its design to the fullest extent possible.

On the other hand, our relationship with raw material suppliers allows us to obtain steels that enable us to achieve higher tensions.

Process Design

A high-tech product, such as the one designed by MBHA Projects, requires a cutting-edge manufacturing procedure.

Our Engineering Department is constantly aiming to enhance the efficiency of our manufacturing operations. This enables us to obtain products that meet our clients' increasing expectations, as a consequence of our extensive experience in the sector.

Product Homologation

MBHA Projects has the necessary resources to test and certify the products it designs and manufactures, verifying that customer requirements are met.

All MBHA certificates can be found on this website, by visiting the Downloads section.

Composites Developments

Ziur is a division of the MBHA Group that specializes in the design and development of composite materials components. Our mission is to meet our industrial customers' demands by providing lightweight structural solutions for the automotive sector.

This division covers all phases of the industrial process, from prototype development to mass manufacturing, developing each stage of the industrial process in-house.

Proposals for element enhancements or substitutions, material selection, design, finite element analysis, prototype production, customer-specific testing, quality assurance, and logistics, among other things.

Join

Would you like to join our company?

The MBHA family is a growing group where people come first. This is why there are people who have spent their entire professional lives with us. If you would like to join our team and work in an innovative international company with an exciting future, tell us more about yourself.

We work from our facilities in Spain and Türkiye to provide the highest-quality products and services.

The outcome is the manufacture of the most technologically advanced, reliable and innovative suspension components in the industry, as a Tier 1 premium partner to the world's leading brands.

Contact Us

Please fill out the form below if you have any questions and we will contact you as soon as possible.